Structural steel is a crucial component in the construction industry, providing the framework for buildings, bridges, and other structures. The process of transforming raw steel into the beams and columns that support these structures is a fascinating journey that involves precision, expertise, and cutting-edge technology. Let's delve into the intricate process of structural blade fabrication, from the initial blueprint to the final beam.

The Blueprint: Designing the Structure

Before the fabrication process can begin, engineers and architects work together to design the structure. The blueprint serves as the roadmap for the fabrication process, outlining the dimensions, connections, and specifications of each steel component. Key considerations during the design phase include:

Structural Requirements

- Calculating load-bearing capacities and designing for strength and stability.

- Determining the size and shape of steel beams, columns, and other structural elements.

Architectural Considerations

- Ensuring the steel components align with the overall aesthetics and design of the structure.

- Integrating steel elements seamlessly with other building materials.

Material Selection and Procurement

Once the design phase is complete, the next step is to select and procure the raw materials needed for fabrication. Structural steel is typically made from carbon steel, which offers high strength and durability. The material selection process involves:

Choosing the Right Grade of Steel

- Considering factors such as the required strength, impact resistance, and corrosion resistance.

- Selecting the appropriate grade of steel based on the structural requirements of the project.

Procuring Raw Materials

- Sourcing steel from reputable suppliers to ensure quality and consistency.

- Inspecting raw materials for any defects or imperfections before the fabrication process begins.

Structural Steel Fabrication Process

With the materials in hand, the fabrication process can commence. Structural steel fabrication involves a series of steps that transform raw steel into the finished components that will form the structure. Some of the key steps in the fabrication process include:

Cutting and Shaping

- Using cutting tools such as saws, lasers, or plasma cutters to shape the raw steel into the required dimensions.

- Precision cutting to ensure tight tolerances and accurate measurements.

Welding and Assembly

- Joining steel components together using welding techniques such as arc welding or MIG welding.

- Ensuring strong and durable welds that can withstand the structural loads.

Surface Treatment and Finishing

- Applying coatings or finishes to protect the steel from corrosion and enhance its aesthetics.

- Surface treatment methods include painting, galvanizing, or powder coating.

Quality Control and Inspection

Throughout the fabrication process, quality control is paramount to ensure that the finished steel components meet the required specifications and standards. Quality control measures include:

Inspection of Raw Materials

- Thoroughly inspecting raw materials for any defects or imperfections before fabrication begins.

- Rejecting any materials that do not meet the specified quality standards.

In-process Inspections

- Conducting inspections at various stages of the fabrication process to check for accuracy and adherence to the design specifications.

- Identifying and rectifying any issues or deviations from the blueprint.

Final Inspection and Testing

- Performing a final inspection to verify the quality and integrity of the finished steel components.

- Conducting tests such as ultrasonic testing or magnetic particle testing to ensure the structural integrity of welds.

Installation and Erection

Once the steel components have been fabricated and passed the necessary quality checks, the final step is the installation and erection of the structure. This involves:

Transportation to the Construction Site

- Shipping the fabricated steel components to the construction site using trucks or other transportation methods.

- Ensuring safe and timely delivery to avoid any delays in the construction schedule.

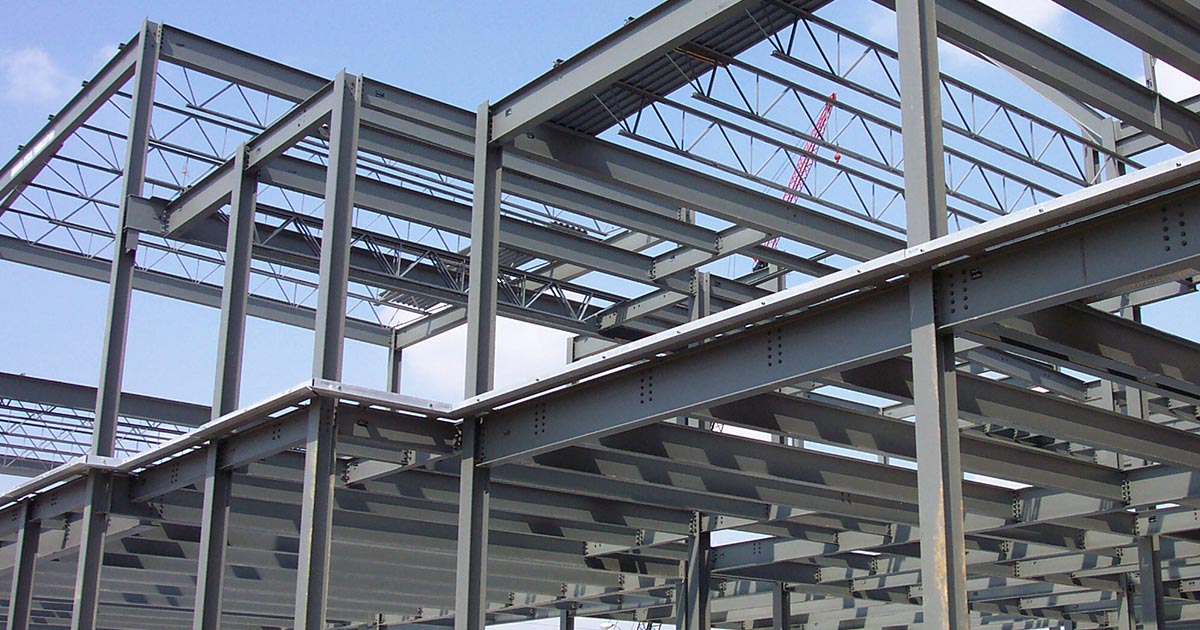

Erection and Assembly

- Assembling the steel components on-site according to the construction drawings and specifications.

- Using cranes and other equipment to lift and position the steel beams and columns into place.

The successful completion of the installation and erection phase marks the culmination of the structural steel fabrication process, bringing the blueprint to life and creating a strong and dependable framework for the built environment.